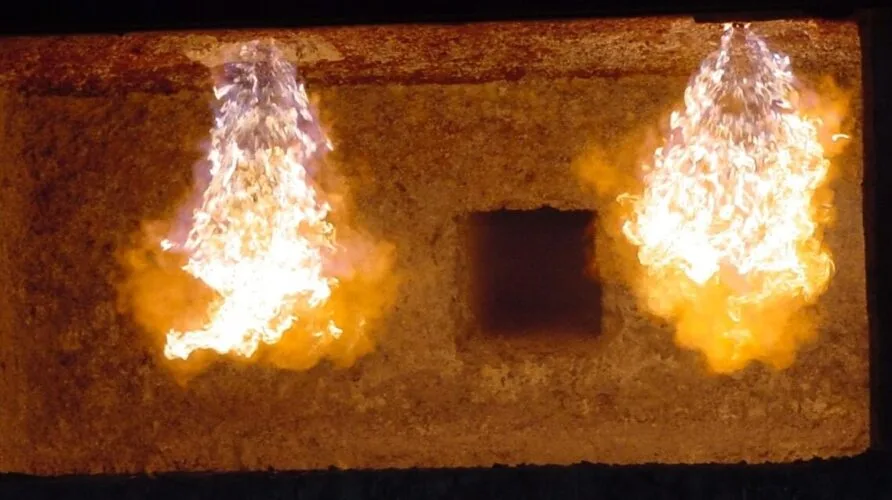

The original QUADRAFLO® Automatic Sweep Burner was developed by XOTHERMIC specifically for the Aluminum Industry. Instead of applying a burner used in other high temperature applications like glass, steel, copper or other industries, XOTHERMIC researched aluminum melt applications and developed, through field trials, an optimal design. This resulted in the highest energy efficiency, lowest dross formation for the best economics. With XOTHERMIC having their head office in the USA, Hotwork International bought the rights on the Quadraflo® Burner technology in order to provide a local service. We are cooperating very close with XOTHERMIC on all projects. Initial start into the aluminum market was the traditional aluminum Reverberatory furnaces. A heat source from the combustion system transfers heat into the cold metal with sufficient force to cause the metal to retain the heat until the melting point is reached, on average 657°C. Further heating is required to provide sufficient energy to maintain the aluminum in a molten state during the final end process of the production cycle, on average 750°C. During this process it is most desirable to do this heat transfer with minimum amounts of oxidation to the aluminum.

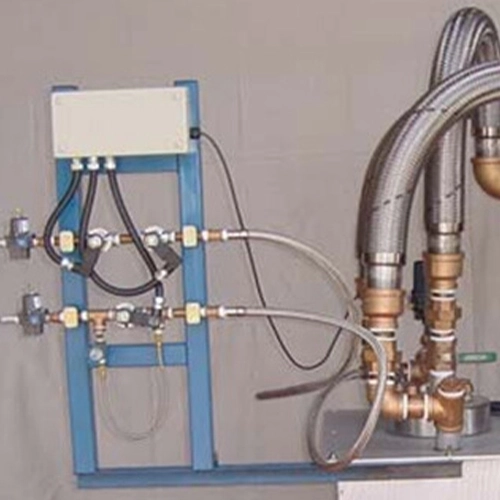

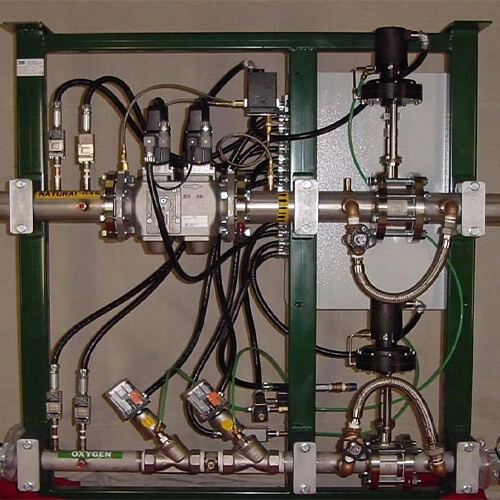

Quadraflo Sweep Burner

Unleash unparalleled efficiency in combustion technology with our Quadraflo® Sweep Burner service. Engineered to redefine the standards of industrial heating, this cutting-edge solution promises superior performance and precise control.

- Proven energy saving from 15 – 60 %

- Typical heat dross reduction 20%+

- High bath coverage / sweeping flame

- Low NOx / reduced CO₂ emissions

- Custom configuration

- Low Maintenance