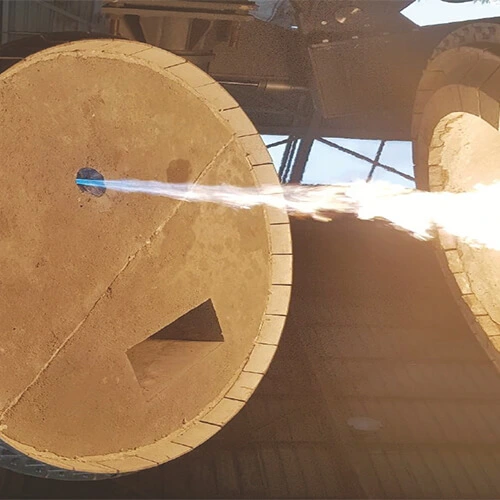

Tilting Rotary Furnace

Services

Furnace Dry-out/Heat-up

Specialized refractory lining dry-out services are provided using specially designed burners to ensure safe moisture removal from newly installed refractory materials. The system gradually increases the temperature, preventing cracking or damage. This method minimizes thermal stress, reduces the risk of steam explosions, and extends the lifespan of the refractory lining, ensuring optimal performance and efficiency in high-temperature operations.

Read more about furnace dry out, heat upProducts

Rotary Aluminum Burner

The Rotary fuel system with OptiFlame Combustion Technology efficiently recycles materials like aluminum, lead, zinc, copper, and tin, including scrap and slag oxides. Using oxy-fuel combustion, it maximizes heat transfer, reduces energy consumption, and improves productivity, metal yield, and refractory lifespan.

Read more about rotary aluminum burner

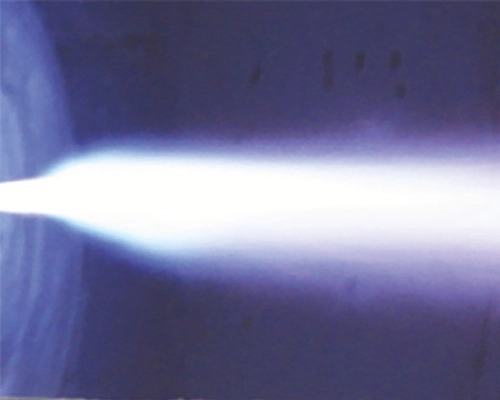

OptiFlame Melting Technology

The OPTIflame Melting Burner combines numerous cutting-edge technologies to offer low OpEx Air-fuel and high productivity Oxy-fuel benefits. It maximizes heat transfer, improving bath homogeneity and productivity with low CO₂ and NOx emissions. Designed for optimal performance, it ensures energy efficiency and fast ROI for furnaces from 10 kW to 20 MW. All systems are Hydrogen ready.

Read more about optiflame melting technology

Oxial Software Solution

Adjusts fuel flow and rotation speeds in real-time to optimize performance and minimize fuel use and emissions. It enhances safety by operating in hazardous environments, reducing risks to workers. The system improves oxygen demand analysis, flame-less combustion, and fuel consumption.

Read more about oxial software solution

IPCU (Integrated pressure control unit)

Designed for low maintenance, it optimizes efficiency and extends refractory lifespan. Manages furnace pressure by most simple and sophisticated way on real-time based on the included pressure measurement. It minimizes false air, reduces fuel waste, lowers CO₂ emissions, and enhances productivity.

Read more about ipcu