Since 1963, Hotwork has provided Furnace Heat-Ups to the major nickel and copper smelting industries worldwide. Our special heat-up technology is based on the use of Hotwork International High Velocity Burners operating on an excess air basis, which have been specially developed for the heat-up of all types and sizes of flash smelting furnaces. Flash smelting is a pyrometallurgical process for smelting metal sulfide concentrates. It is used primarily for copper sulfide concentrates, but it is also used to a significant extent for nickel sulfide concentrates. Flash smelting furnace (FSF) technology is one of the most widely employed methods for copper smelting. Developing an understanding of the impact of the process parameters on smelting operations through modeling is the key to improving smelting efficiency.

Flash Furnace Services

Optimize the performance and longevity of your Flash Smelting Furnace with our specialized Flash Furnace Services. We provide expert refractory maintenance, heat-up, drying, and operational support to minimize downtime and enhance efficiency. Our tailored solutions ensure safe, cost-effective, and reliable furnace operations.

- Furnace Heat Up

- Furnace Cool Down

- Furnace Hot Hold

- Extended Refractory Life

- Reduce Risk of Steam Explosion

- Cost Effective

- Even Temperature Distribution

Uniformed Heating & Control

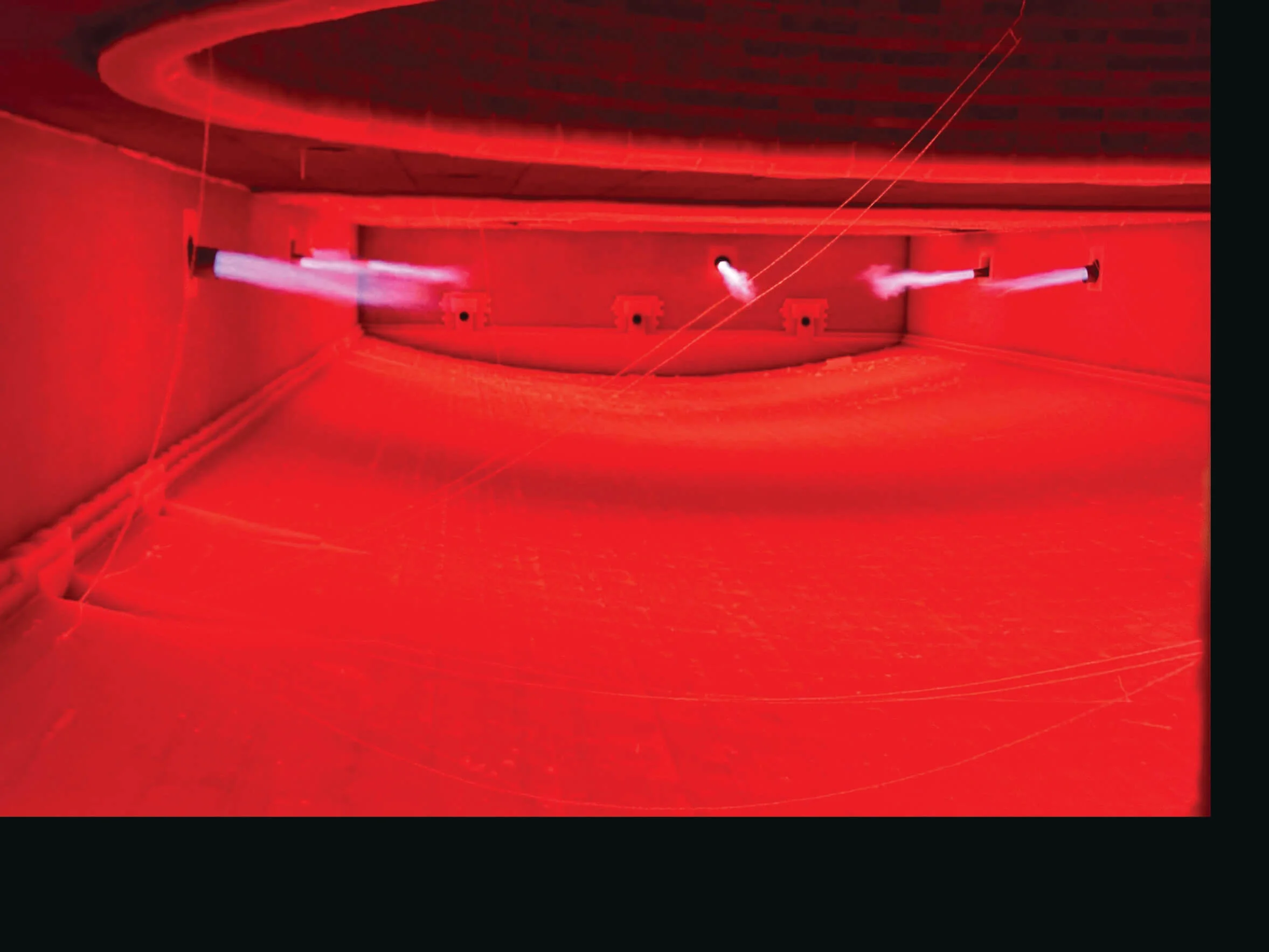

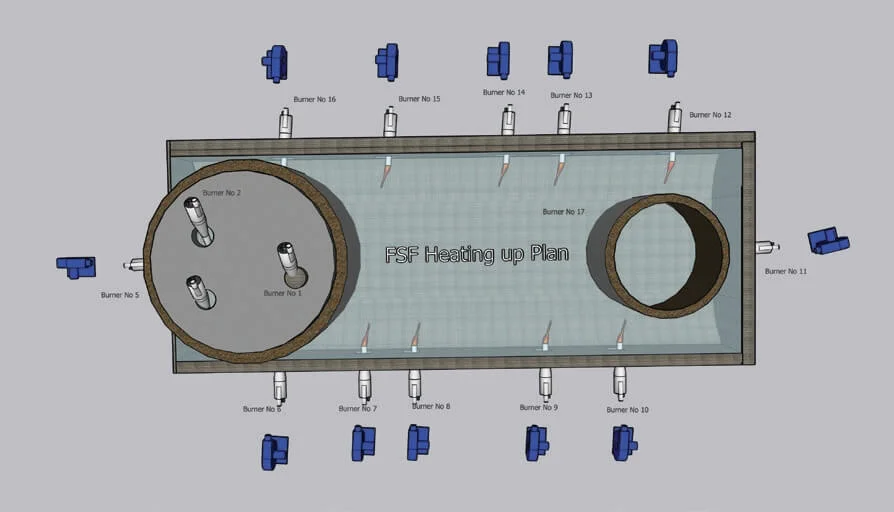

The reaction shaft is the heart of a flash smelter. Current knowl edge of the combustion of concentrate and ancillary fuels (coal, oil, and gas) indicates that flash smelting involves continuously blowing oxygen, air, dried particulate sulfide concentrate, and silica flux into a 1300°C furnace. The principal objective of flash smelting is to produce molten matte that is richer in nickel (and other metals) than the original concentrate. Our burners can be positioned

through nearly any reasonably sized furnace opening, enabling precise placement of heat input to ensure uniform temperature distribution throughout the entire volume of the furnace. High Velocity Burners have a turndown ratio of 100:1, allowing precise temperature control within the range of 80-1400°C. Each burner is capable of an adjustable output of 2.5 million kcal (10 million BTU) and over 5,000 Nm³ of hot gas per hour.

What is Refractory Dry-Out?

Refractory dry-out is the process of removing moisture from refractory materials, such as bricks and refractory castables, after their installation in high-temperature industrial applications. This is important because refractory materials are designed to withstand extreme temperatures, and the presence of moisture can cause them to crack, spall, or fail when exposed to heat. During the dry-out process, the refractory materials are gradually heated to

remove any moisture that may be present. This is typically done by slowly increasing the temperature over a specific period of time, allowing the moisture to evaporate without causing thermal stress. Both vaporization and diffusion play crucial roles in the refractory dry-out process.

Location:

Being an international company, we reach any location worldwide. With over 600 burner sets and equipment stored in our own hubs in Switzerland, India, China, The Philippines, Indonesia, and Mexico, Hotwork International offers fast and reliable service at any location worldwide.

Manpower:

More than 600 highly qualified service engineers guarantee smooth project completion at the highest quality and safety standards. Internal training and external safety measures are introduced, along with internal and external evaluation of all burners and electrical components, certifying the safety and performance.